Stronglight cotterless cranks

Posted: Wednesday 12th August 2020

Until very recently the fitting of cranks to bottom brackets had been standardised with a square taper design. The origins of this are not commonly known. This is rather surprising for the originator of this design is still in business making chainsets – you would expect them to be shouting about just how clever they were. Stronglight (who are now part of the French Zefal group) were the innovators of the square taper crank/bottom bracket fixing system back in the mid 1930s. Not much is known about how the design came about, or even the exact date of introduction, although it is thought the 49D design was launched in 1936 and that a steel version of the 49D (probably called the 49A) was launched a little earlier, rumour has it in 1933.

Until then almost all cranks had been fitted to cranks with tapered cotterpins – this was a very crude system of fastening. Cotterpins could be very difficult to remove if left in for a time and mostly required careful filing to get a correct fit. Stronglight’s cotterless system was simplicity itself – the cranks could always be removed easily as long as you had the extractor and fitting simply required tightening the crank into place.

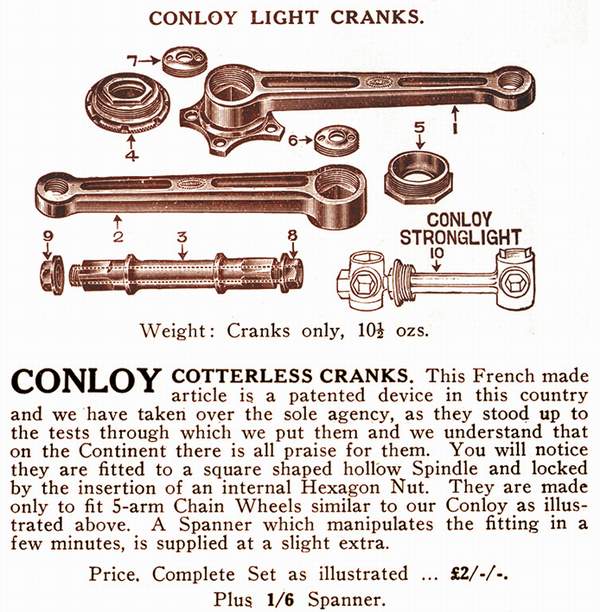

But by 1938 Stronglight 49D chainsets were being sold in Britain by the Constrictor company. Constrictor in the 1920s and 1930s were responsible for bringing some really quite innovative products to the marketplace – in another Design Classic we have looked at their Conloy rims. Many of the cycle parts and accessories they sold were designed and/or were manufactured by somebody else. But they looked upon by cyclists in that time as being at the cutting edge of cycle technology. The 1937 Constrictor catalogue featured Stronglight’s new cranks under the heading Conloy Cotterless Cranks and mentioned the fact that they were made in France

The cranks were made of aluminium alloy (Dural hence the D in the name 49D) and fitted onto a bottom bracket axle with tapered squares. They were held in place with nuts on on threads that protruded from each end of the axle. This was practically the only difference from modern cotterless square taper designs which use a bolt. It is not quite certain whether they were available in quantity in 1937 as in the 1938 catalogue Constrictor writes “We have had a few of these tested during the last year and they have all proved satisfactory.” In the 1938 catalogue a steel cotterless crank with three arms to take standard continental type chainrings was also offered. They were certainly expensive, costing £1 15s in 1938 compared to the top cranks from BSA (which were always considered the best available) which were priced at 14s 6d. Only single chainwheels were available. But they were the first reliable aluminium crank – it is rare to find a broken 49D crank. Cottered aluminium cranks which were made both in England and France suffered a large number of breakages.

After WWII Constrictor did not import the cranks again – it was left to another British import company, Fonteyns who started to bring them in by about 1950. Interestingly they referred to the single chainwheel version of the model we now know as the 49D as the 32. I do wonder whether Stronglight renumbered their models just a little later. And even more curiously recommended only using a double chainwheel with the steel cranks which they did call 49A (A for Acier, steel). Both the steel and aluminium cranks were now fastened to the bottom bracket axle by bolts rather than nuts.

A few years later – certainly by 1955 – the British importers had changed again to Evian and from then on the 49D designation was used.

In 1957 Stronglight launched the type 57 Super Competition set. This was designed from from the beginning to use double chainwheels with a large modern type 5-arm spider with 122mm bcd able to take chainrings down to 38T. This was truly modern in concept and pre-dated the Campagnolo Record chainset by a year. And Campagnolo went ahead and copied Stronglight’s square taper bottom bracket fitting – only the extractor threads were different. And the rest as they say is history – the square taper design was gradually adopted during the 1960s by almost all chainset manufacturers and of course became the standard until Shimano broke the mould with their splined chainset fittings on MTB chainsets in the middle 1990s which later filtered down to the road sets.

Tip

Crank Extractor This uses a unique 23.2mm thread which is very similar to the TA. But do not use a TA extractor, it will strip the threads in a Stronglight crank. The Stronglight extractor can be distingushed from a TA one by a shoulder at the base of the threads.

Dating Guide

Early cranks have a shallower engraving and pre-war ones sold in the UK are also stamped Conloy on the reverse side. They were fitted with dust caps with two pin holes. The two pin hole dustcaps remained until the early 1960s. Dustcaps after the early 1960s had a screwdriver slot. All cranks prior to the 1960s (and probably for sometime into the 1960s) are stamped Stronglight with Deposé beneath. Later cranks are stamped with Marque above the Stronglight and Deposé below the Stronglight stamping. In the early 1980s Stronglight adopted the standard 22mm extractor threads. Another more subtle difference is that the earlier cranks are quite a bit more slender with larger flats on the edges – later ones are very square in shape.

Different Models

49A 5-pin cranks in steel

57 5-arm cranks introduced 1957 with 122mm bcd and available with triple chainrings

63 Almost identical to 57 but with larger bolt holes for allen bolt chainwheel fittings

The 57 model did not have rings down to 38 teeth, although the BCD indicates that this should have been possible. This was due to the design of the ring, which continued the line of the spider further out towards the teeth, and is easier to view than describe.

The smallest inner ring available was 44 teeth, as was Campag at that time. Racing men seemed to use bigger gears uphill in those days!

In 1963 (I assume) the Model 63 was introduced. The only difference was that the ring was redesigned so that an inner ring down to 38 teeth could be fitted, together with the neater allen-bolt sleeve to hold the rings in place. The 57 used a smaller sleeve, more like the dimensions of the TA bolts so familiar to us.

Shops like Condors did a roaring trade drilling out customers 57 crank arms and fitting the 63-type rings, so the unaltered 57 is rather a rare chainset these days.

By the way, mine was fitted with the slot type dustcaps rather than the pinholes, so I think these must have died out earlier. Although using the 44 inner with a large outer enabled the racing cyclist to use a straight through block with 1 tooth increments, most British cyclists continued to use a 14 – 24 block with 3 teeth difference on the chainrings. This meant a double change each time to find the next closest gear, but it did not seem to bother any one.

Posted: Wednesday 12th August 2020

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.