Querée Brothers

Posted: Thursday 04th June 2020

Starting with a 1994 interview with Berkley Querée:

“During the war, on the rare occasions when Wint and I got together, we often discussed what what we would be doing after the thing came to an end, and these discussions eventually came round to the idea of commencing business on our own account in the cycle trade as soon as things got back to normal. As with all things the war eventually came to an end and what seemed an inordinately long time after that, came my discharge. A few further thoughts having been exchanged between us we decided to ‘go for it’.

Work began immediately on the establishment of our business-to-be. Premises were secured after a long and apparently hopeless search, for many were in those days seeking to start businesses, and many buildings had suffered from the ravages of war. As we required premises not too far from where we lived, our chances were further restricted. When the School Road premises were eventually found and secured, much work needed to be done to fix it up for the kind of work we were going to do; this entailed obtaining suitable timber- no easy task, and then constructing benches and other fittings. Tools had to be obtained and supplies of accessories and materials. Against the background of those rather miserable times, it was a very testing period and had we known of the trials to come we might well have decided to throw in the sponge before we had gone even this far.

The business opened in the first week of May 1946 and business was not very encouraging at first. However, due mainly to Wint’s connections with the cycling fraternity, we soon had a few visitors interested in what we were about, and in the mysterious way that these things have of getting around we soon became reasonably well known. Our policy was always to give the absolute best service to our customers, whether it should be a small boy with his ailing machine, or a racing man seeking ‘something new’. We had already decided that we would make some lightweight machines of our own and although the going was rather hard at the time, we set about making our first frame that year.

This first was of rather unusual design – forced upon us almost by the great difficulty at that time of obtaining many of the manufactured special parts such as lugs of a suitable form, as they were virtually impossible to get. So we decided upon a hybrid. This frame was constructed in the normal way as far as the rear end was concerned, that is the seat lug and bottom bracket. Lugs for the head of a suitable angle in pressed steel were not available so we made a frame using a technique known as bronze welding. This is a form of brazing in that it uses a lower temperature than steel welding, and was not really welding at all, but it allowed a generous supporting fillet to be placed at the head tube junction.

The method required the mating tubes to be ‘scarfed’ or contoured to a true mating shape; besides this a jig had to be designed and made to maintain the required juxtaposition during the welding process. It is not known whether the frame survived. A further novelty was the fitting of an aluminium plate on the down tube upper face bearing the engraved name ‘La Querée’. This frame was quite successful and proved to be a delightfully responsive ride, and was made up and used by Wint for some time. It was the only frame in the first year as we were occupied with more mundane tasks, of necessity, because the everyday working of a cycle retail and repair business is of its nature mundane. There were always opportunities to work out a few new ideas and to continue with more everyday activities such as wheel-building, enamelling, and so forth. We were extremely glad to see any kind of bicycle being brought in for repair because trade in general was very poor.

We soon found out that we were getting the kind of work which other businesses were either not inclined to take on because the profit margin was not high enough, or because they simply did not have the expertise, an instance being that of one branch of a well known cycle retailer in King Heath sending customers to us for free after sales service!

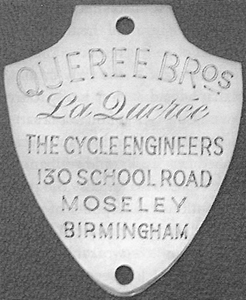

Badges are rather important to the maker and user alike. The owner of the machine likes to display to the world that he or she is in possession of something special, or at least something that has an identifiable origin, and the maker wants his wares to become known to all and sundry. It also indicates the makers confidence in his product. We decided to have a metal badge. We would have had a metal and enamel badge but that would have meant ordering many more than we could envisage using for quite a long time, and the price was prohibitive in our delicate financial state.

The aluminium and brass badges were made by us to our own contour, and were hand engraved by a professional. It is not possible to say how many of theses were made but their use was definitely confined to the earlier models, as also was the distinctive metal lettering on the down or top tubes, though one machine of our make was furnished with such letters in later years with our blessing. Later machines displayed transfer badges and lettering of the normal kind. These were supplied by various firms, initially Harold Peace and later Butcher and Co.

Our first machines were not numbered, as they were made for our own purposes, and frankly we did not have a suitable set of number stamps; besides which there were other more important calls on our slender resources. From the latter part of 1947 all frames were numbered and the sequence was arbitrarily changed at frequent intervals. A record was kept but it not now to hand. Again on the subject of badges and other identifying marks, it was always our intention to have distinctive and stylish embellishments of this kind to encourage pride of ownership, as that was something we like to see. However, the cost proportion was too high at a time when the total price of a frame was rather critical, so we had eventually to resort to more mundane forms of identification. In this connection, when hand-cut lugs were provided, it was almost always at the request of the person ordering a frame and naturally this resulted in what one would nowadays call a ‘price enhancement’. The absence of such embellishments did not make our frames any worse, though it was something we regretted not being able to provide as a matter of course.

We knew quite a bit about plating as some of our early work experiences were concerned with this trade, though we were to extent governed by what kind of finish was given to components by individual makers of parts. We were rather selective in this field and finish always found a high place in our standards. Enamelling was somewhat different, as even in the early days we were able to exploit a fairly competitive industry. Originally our first few frames were enamelled by Rossiter of Highgate.

Later we used Midland Enamellers of Balsall Beath, followed in the last period by Neal of Small Heath. In the earlier period of the business frames were mostly made to customer’s orders and specifications. A few specials were also built to try out various ideas. One built for my own use used a 1 1⁄8″ diameter head tube in place of the usual 1¼” diameter. This frame had the normal pressed steel head lugs with a liner fitted, allowing two fretted patterns to be used at the front. The seat stays were also of unusual pattern in that the top end was not sealed off with a plug shoulder but had an open cut away top end passed through a slotted seat lug peg. This was quite a distinctive machine its 26″ Kuntdz wood rims and one or two other small innovations

We were always great believers in joining frames by the use of silver solder. The tubes used in lightweight frames were seldom of heavier gauge than 22g (a thickness of 0.028″), to the application of high brazing temperatures for long enough to ensure a complete flow of brass into a joint seemed a bit punishing to us, despite the fact that it was in common usage, and still is. We therefore intended originally to adopt silver soldering as our standard procedure, but circumstances did not allow us to apply this process to all our frames, particularly the more competitively priced versions, which, by the way, we were still not ashamed to have bearing our name.

Despite all efforts, business did not come up to our original expectations and the exceptionally severe winter of 1947 did very little to help our future prospects, coming less than a year after our start. Heavy snow and ice coupled with frequent power reduction, or cuts, during week after week of Arctic weather gradually brought about an almost complete cessation of business. Throughout this time the shop was opened each days and many passed without a single visitor. The shop had to close at dusk because of the absence of light, and of course heating was completely absent from the shop. Our slender capital was gradually eroded away, and when the weather eventually broke in April we were in difficult circumstances, reduced to accepting any kind of work which was in our resource to carry out.

When the summer of 1947 came we were miraculously still solvent, and once more business trickled in. More frames were built using the silver soldering technique and we now used the ‘bullet’ shaped seat stay heads for the first time – these were discontinued in later years. We also offered a similar design in cotter pins. On the subject of fittings we had intended initially to incorporate the high quality Chater-Lea bottom bracket sets in our frames. These used a larger diameter ball and were consequently a little larger in diameter than the standard and required the brackets to be reamed and re-threaded. This proved to be rather time consuming, so after a few frames it was discontinued. We also introduced at that time a new concept in chainsets, also by Chater-Lea, using an extremely slender round section crank. Experience showed that this component was insufficiently strong and liable to fracture, and it was withdrawn by the makers after we had made representations on the grounds of safety.

Many discussions took place with the various representatives who called on behalf of their firms. The functions of these people was not to receive orders for goods – this was the job of the traveller, through with smaller firms these occupations were combined. We were frequently able to pass on new ideas and current thinking among the cycling fraternity in this way to manufacturers. In the course of doing this we did rather trustingly divulge a few observations that would have been better kept to ourselves, and on occasions saw our own ideas mysteriously incorporated into new products. On one such occasion Wint went into some detail for the proposed improvement that he had himself tried out on a well-known gear system, only to find some time afterwards that it had become an accomplished fact.

Needless to say, that rep did not receive any other titbits. Quite a few innovations were produced at different times, including coupled cable brakes. These observations are intended to show that we were not content to become just another cycle firm churning out the same old stuff and having no further interest in our chosen trade than the making of money. If that had been our sole object the business would have been closed in it first year.

We believed very much in the principle of true customer relations, and to that end became members of the new post-war establishment of the Earlswood Road and Path Cycling Club, where after a short while Wint became Vice-President and Timekeeper (when he was not himself riding in events). We both took upon ourselves the editing and production of the club magazine for some years, producing the said journal at home with a duplicator made up by ourselves. This paper incorporated cartoons and photographs – long before the arrival of modern methods of reproduction. We like to think that our association with the cycling world in these ways formed a positive contribution to the pastime and also gave us a closer insight into the needs of the people for whom we were trying to cater.

We had always recognised the importance of variable gears on the bicycle and watched with interest the development of this component. Sadly, the British-made devices always seemed to lack the necessary ingredients for a really attractive, fast changing and reliable device. When this came it was from the Continent. Much effort had admittedly been put in by cycle component makers in this country but all the trouble taken had failed in those respects. The Trivelox satisfied the need in the early thirties, mainly for riders of the very heavy touring tandems of the period, but it was a rather cumbersome device at best and because of design limitations could really not offer more than three speeds.

The products of the other main supplier of such gear, Cyclo, certainly produced fairly well thought out and workable gears, though in the early days users of these devices were sometimes unkindly known as the ‘black hand gang’ for obvious reasons. At the time these gears were suitable mainly for the tourist. It should of course be remembered that in those days road racing on bicycles was rather restricted in this country, and generally road time triallists preferred to follow track practice in using fixed single-speed gears, sometimes in longer distance events allowing themselves the luxury of a reversible hub.

It was the Simplex gear from France that offered the first introduction of the new type of gear, which after its use by a few riders just after the war virtually became standard on the machines at the beginning of the new mass start racing movement, and for that matter on the new type of touring machine. Although some work was done by a Birmingham gearbox manufacturer to design and make a form of bottom bracket gearbox for bicycles just after the war this did not succeed and the derailleur system now reigns supreme, though it still seems mechanically inelegant. I flirted with the idea of a variable gear using a type of expanding chainwheel, but it would have required a substantial amount of development time, not to say expense, and with no guarantee of success this idea, along with several others, had to be discarded.

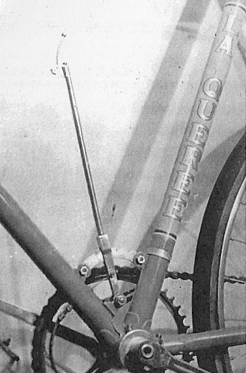

In the early days of 1948 we decided to exploit the positive nature of gear positioning on the Simplex by trying out a gear control with fixed positions, as tests had indicated that the idea was feasible. The control was sited in the angle above the bracket formed by the down and bottom tubes and consisted of a steel quadrant of approx. 2½” radius. On its centre was pivoted a lever carrying a spring-loaded plunger that indexed into a notch provided in a suitable position on the circumference of the quadrant, which being of a larger radius than normal allowed more accurate positioning than the small diameter motor cycle type of control lever normally used.

The plunger could be withdrawn by operating a small lever at the top of a 9″ long ¼” diameter tube screwed into the lever after the trails .only modification needed was to replace the notched positions with a ratchet form of location such that the lever, when pulled back, would automatically engage, and each gear change in the other direction was made merely by releasing the plunger. This original model, in chrome-plated form, was fitted to Wint’s machine and remained there for many years. We found a reasonable interest showing in the device, so much so that we took the chance to go into limited production.

The production model was not quite as labour intensive as the original – economically it just could not be! The new version was made from aluminium castings from our patterns, other parts being fabricated for us by a small machining shop of an acquaintance. It performed excellently and I used on myself for a considerable time. The controls were originally clipped to the frame by cast aluminium clips. Later, in line with the established fashion of brazing (silver soldering in our case) small fittings to the frame, we began fitting lugs.

It is pleasing to know that some of these change levers are still in use after to many years. Later development of this component would probably have been in the direction of a positive change lever similar in action to the motor cycle gear change system where one gear up or down is selected by a single movement either way. That this and other ideas were not pursued was due to the immense demands made by day-to-day affairs. I was personally interested in the reintroduction, in a modified form, of the back-pedal brake operated from with the bracket.

One activity which formed a big part of our business, particularly in later years, was the building of wheels. The same care and attention to detail was exercised here and we acquired an enviable reputation in this field, supplying other lightweight cycle firms as well as cycle factors. This aspect of our output in later years involved other work being transferred elsewhere as there was no longer sufficient room for activities such as making up frames on the premises. It should be emphasised, however, that nothing was ever produced by us that did not come up to our standards, as may be shown by the fact that even today we hear of some of our machines still in use, and the certain knowledge that quite a few of our frames soon will be carrying riders fifty years after they were first wheeled onto the road. We suppose that is some reward for our efforts, particularly those of Wint who held the fort for so long. Dare we hope that one of them will see its centenary?

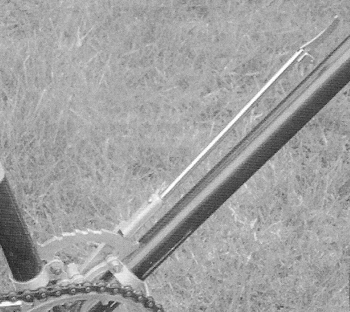

Later versions of the gear mounted on braze-on frame bosses had cable routing through the down tube to Simplex changer at the rear. It is also possible to see “LA QUERÉE” seat tube transfer. This was on Winter Querée’s own bike.

At the end of 1951 in spite of the amount of work we had done in the previous five years we found that the business could no longer sustain both of us full time. I therefore left the business for employment in the technical college at Aston. Wint, who had during some of the difficult early days, worked as a manager at Simpson’s Cycles on the Stratford Road, and later as representative for a cycle components firm, now carried on, holding the fort for another twenty years, but all hopes of further development had to be relinquished due to lack to funds. He dearly wished to be able to move to larger premises, install new equipment and establish a showroom, and of course, a workshop on the premises.

At the end the house which incorporated the shop at 130 School Road was condemned and though Wint continued for a few more years in temporary accommodation on spare ground at the side of the old premises, he decided, reluctantly, to call it a day and take early retirement to pursue his other great love, painting in oils, something that very few knew about. For myself, I never really got back to cycling, which in many ways I have often regretted. When I retired from Birmingham Poly I spent most of my time researching and making replicas of early lutes!

The name Querée is from the Channel Islands rather than France (in its Anglicised form it is spelt ‘Carey’). The Channel Islands originally belonged to the Dukedom of Normandy and after the Norman conquest of England became part of the English Kingdom. The use of the definite article ‘Le’, sometimes used in earlier days as a prefix, was re-adopted by us, though in its feminine form because it was to be applied to a bicycle, as perhaps adding a Continental flavour to our name, so there was a sound and not contrived reason for its use in this way.”

My first visit to the Querée cycle shop at 130 School Road, Moseley, Birmingham was in 1947. In those post war years finding new 27” high pressure tyres was very difficult and most Saturdays were spent riding round to all the cycle shops searching for these elusive items. A fellow cyclist at one of the shops, learning of my search, asked if I had “tried the new shop” at the Kings Heath end of School Road. I set off at once and found this new, freshly painted but quite small shop open for business and manned by Berkley and Winter Querée. I did not obtain any tyres but I did acquire, gradually, two new friends.

The shop was, in fact, the front part of an end terraced house and had previously been a greengrocers. Berkley and Winter partitioned off a small area for customers to stand whilst being served, the remaining part being the workshop. Some idea of the size of the establishment can be gained when I mention that four customers at once comfortably filled the waiting area, any more than this involved a complex set of chess–like moves to allow the shop door to be opened.

Despite its small size the shop soon attracted the keen lightweight and racing types and Saturdays in the summer months would see a mouth watering selection of bikes cluttering up the hard standing in front of the shop as the riders made their purchases or just chatted. Fortunately both Winter and Berkley were very easy going and amiable characters with a very dry sense of humour and never seemed to mind the premises being taken over in this way although I sometimes wonder if the presence of all these hard riders did not perhaps deter the occasional “normal” cyclist wishing to buy a lamp battery or some such item.

By this time the Querée Brothers had started building their own frames which, after testing, they were happy to produce for customers. These were titled “La Querée.” The frames were silver soldered and had hand-cut lugs and distinctive little features in the form of hand made pump pegs and seatstay tops. Most made use of transfers for the head and down tube but some had aluminium head badges and a few had brass head badges and the words “La Querée” in brass letters soldered into place which made the frames very distinctive. These brass items were costly to make and very time consuming to fit so they were soon discontinued. Suddenly, the Dawes had lost its charm.

Before WW2 Berkley had been a motorcycle mechanic and had equipped his pedal cycle with two modified twist grips one to control the three speed Sturmey Archer hub and the other the front changer. Some time later Berkley sold this cycle to a man who came up from Southampton to collect it and set off to ride it back there; he may have arrived by now!

With the cycle shop in operation the brothers began experimenting with their own design of gear mechanism which worked well but which they could not afford to produce. To work with this gear they had also designed a positive stop gear lever which they could produce “in house” and as they were now on with an up dated version I was able to purchase one of the original type they had been using themselves. This early version had an alloy quadrant mounted by three alloy clips round the seat and down tubes just above the bottom bracket. From the pivot point an alloy and steel lever projected upwards to a convenient height and had a small spring loaded trigger at its top. Indents in the top of the quadrant located each gear position as the lever was moved backwards from the down tube towards the seat tube and, to go back through the gears, the trigger could be flicked to move one step at a time or, by holding the trigger, the lever could be moved in one sweep over all five gears. Used in conjunction with the Simplex of the day this was a superb gear change.

The later version of the gear levers used just the arc of the quadrant bolted to lugs silver soldered to the seat and down tubes with a separate lug for the lever pivot. The base of the lever was now an alloy casting with a chrome plated tube leading to the trigger although I do have an all steel version that Winter was experimenting with. Before fitting it to my road bike I had the frame re-enamelled in green lustre with a candy floss pink (!) panel on the seat tube. With polished brass letters and head badge the machine looked superb. It had been my intention to keep this machine until I was too old to ride any more, but in my later Morgan three-wheeler years, I lent the bike to a friend of mine who was in need of transport, but it was stolen from where he kept it.

Fortunately, the bike was in fixed wheel form when I lent it and I had the Querée lever and the Simplex mechanism safe at home. Shortly after the shop opened a German couple who had lived in this Country since before the war offered the brothers a pair of Siddell and Naumann ‘his and her’ cycles. These had been made in Dresden and they had brought them over when they came to live here. The brothers purchased the machines and used them to ride from home to the shop and back each day including through the terrible winter of 1947. The bikes had the wheelbase of a bus, yellow painted steel rims with 2” balloon tyres, a Torpedo back pedal brake and a cotterless steel chainset. They also boasted a front brake which, when used, pushed a steel pad down onto the front tyre but as the sudden use of this item resulted in impromptu flying lessons these were soon removed.

Winter Querée had the ability to ride at a pace that was fast yet effortless and appeared to go along the flat and up or down hills at the same speed. He was of slight build, had dark curly hair, was well tanned and would not have looked out of place in the Tour de France. Berkley had a more casual approach to riding and was always willing to stop and aim his Baldinette 35mm camera at something which attracted his attention.

Posted: Thursday 04th June 2020

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.