Philbrook, W W 'Bill'

Posted: Saturday 06th June 2020

Introduction

It seems hard to believe that perhaps one of the most important ‘London’ bicycle frame builders of the last half century is not represented more in print and on the internet. Twenty years ago, Nick Sands, then a member of the V-CC wrote an informative piece in their magazine News & Views to try to make Bill’s career and talents more widely known inside the club. In 2010, V-CC member Norman Cole having suffered a bereavement revealed to me in a telephone conversation that he had been collecting information on Bill for a number years and this included photocopies of magazine and newspaper articles sent to him by Bill’s wife Mary.

Norman had in fact two solo frames and a tandem made by Bill. Perhaps the most important document was a copy of Bill’s frame building book containing a record of every bike frame he made under his own name but sadly not a record of the many hundreds of frames he built for other people. The dossier compiled by Norman was kindly sent to me with the promise that I would try to write an article based on its contents. As time has passed by so quickly, I thought I would just attempt something without reference to his surviving family but since then I have had a conversation with Mrs Philbrook, now 87, to discuss the contents. Hopefully those more knowledgeable than I will add to the information and rectify any serious inaccuracies.

Bill’s Career

Of the ‘London’ bicycle and frame builders from the post-war period there is probably no one held in higher esteem than Walter William Philbrook known as just ‘Bill’ or ‘Phil’. He was born on September 25th 1916 the son of a railwayman in the South East London suburb of Sydenham not far away from Crystal Palace. Like many of his generation he left school at the age of 14 and ‘with a fascination for bikes’ began an apprenticeship with the bicycle builders, Buckley Brothers whose premises were I think at that time at 61 Dartmouth Road, Forest Hill. Buckley Brothers had a fine reputation for making high quality lightweight bicycles in the pre-war period and one of a small group of South London firms that included Selbach and Granby that were building with ‘taper tubes’.

They were famous for producing one of the lightest bikes at that time which weighed only 13lbs and displayed at the first Lightweight Show as well as a 22lb tandem frame. Buckleys were not just cycle makers but innovators, patenting a strut between the bottom brackets of tandems, designing triangulated chain stays and ‘rigidride’ frames. The build quality of each frame was ‘par excellent’ and the attention to detail must have influenced Bill in his formative years.Norman Cole believed that during WWII Bill joined the army as an armourer (as was Bill Hurlow). After the end of hostilities he joined A S Gillott in 1946, a company revitalised by Harry Carrington. There, he was in the company of Len Hart, George Holt, Jim Collier, ‘Doc’ Green, Ron Cooper et al.

Bill was also a keen club cyclist, a member of the Sydenham Wheelers and at one time their 25-mile club champion and he was to go on the become their President. He married Mary in 1948 who was ten years his junior and apparently built her a superlight frame as a wedding present according to Sands. They had two sons – Glen and Robert and two daughters Anna and Shelley. Sands writes that ‘the family was still transported on a tandem with a sidecar until Bill eventually purchased a Panther motorcycle.’ The family ‘moved to Farnborough in Kent in 1954’.

Bill must have been amongst a number of Gillott frame builders that departed from Gillott in the late 1940s and early 50s. Jim Collier seems to have worked for a number cycles shops as a trade builder from around 1950 and Doc Green worked at back of Algurn in Wandsworth from 1948 before opening his own shop in Fulham in 1953. Norman noted that Bill left to return to Buckley Brothers around 1950 but went on to work for Claud Butler shortly afterwards when Cliff Shrubb arrived as an apprentice, although a copy of a photo showing Bill with other frame builders at Gillott astride a ‘quin’ sent to Norman by Mary is dated 1950. According to Cliff, Bill was Assembly Shop Manager in charge of quality control, scrupulously checking everything that went out, including tracking and had to rectify any mistakes. He was to remain there until about 1956 but left before Claud Butler went into receivership in October.

The commuting from Farnborough was always difficult and he could see that CB was already in difficulties Mary told me. Sands mentions a move to Holdsworth who bought the Claud Butler name and relaunched the CB brand. However, he was to leave after a short period. There is a note made by Norman to suggest he have spent time at Andy’s of Beckenham and then Avery Weights but his heart was always in cycles and cycling. Then in 1959 he appears to have hitched up with Pete Benedict the proprietor of Meridian Cycles at Sutherland Road, Forest Hill and helped to build the Grandini, Meridian and Metro marques along with the frame builder Harry Healey (Paris, Hercules, Don Louis). Bill was probably responsible for the creation of the Grandini drop-outs and possibly the internal reinforced ‘Meridian’ fork crown. Later on he created his own unique drop-out of extraordinary beauty. (See images of Philbrook dropouts below)

Norman’s notes state the Philbrooks moved to Gillingham on May 13 1959. According to the Nick Sands article, in 1959 after a visit to Rochester to see a relative, his wife Mary came across a double fronted rundown shop at 4 & 6 Arden Street, Gillingham, Kent with accommodation above it. They were to move in that year and Bill was all set to build frames for the trade and under his own name (PAG = Philbrook –Arden Street- Gillingham) for the first time and he joined the local Wigmore Cycle Club. By 1967 the accommodation above the shop was declared unfit for habitation and the family moved to Rochester according to Sands. Despite this it did not stop the use of downstairs workshop which remained in use for a further 25 years.

Bill produced frames for Meridian Cycles alongside Youngs of Lewisham but perhaps one of the most extraordinary customers was C&K of Penge a new manifestation of Claud Butler and his nephew Keith, one of his attempts to re-launch himself. Pete Holland was persuaded by Claud to see ‘his builder’ for a track frame in the mid 60s. Bill was to build for Harry Perry and Ken Bird amongst others but no record of this activity survives. Sands and Bogdanowicz both mention a small punch mark that was placed under the right chainstay to identify frames built for others and this is corroborated by Keith Perry. However, owning a Meridian and a Grandini known to have been built by Bill and a number of other frames which were strong candidates I found none in this location. However, the punch marks do exist but just not in this location but once identified are consistently in the same place providing a eureka moment when discovered.

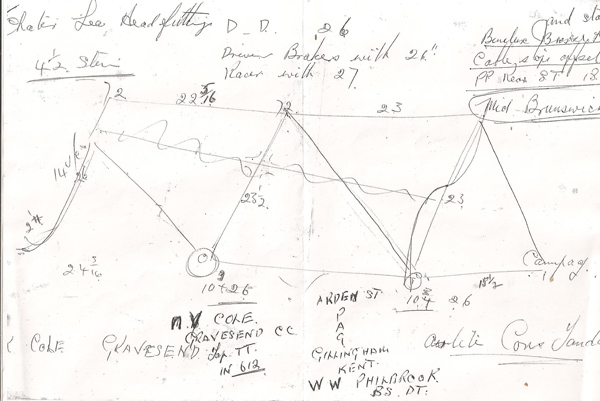

Bill’s Frame Building Record Book and Practice

Mary writes on a ‘post-it note’ ‘It was an old Railway Drivers Time Book an Uncle of mine gave to Bill – he was always going to get a new one – but never did as you can see!’ ‘The black parts are because the book was well worn and a bit greasy as it was always in the workshop. We moved to Gillingham in May 1959. This book was started for Bill’s own frames in 1960’

The book contains the frame numbers on the left followed by ten columns of measurement details. The name and address of the customer appear on the opposite page. The last full entry is for a tandem frame no. 332862. Generally speaking it is a sequential number followed by the year and then the month of build.

Some years look very lean with only five frames listed but he probably had unrecorded trade work to supplement it. However, Bill was also known to be slow but precise. Sands states ‘Although there was always a waiting list, typically 6-8 months, a favoured customer could get a frame in just over a week if it was wanted for a special event. All work was carried out on the premises, including the stove enamelling…..’ This was carried out in a converted metal cupboard according to Norman. Interviewed in a ?Seattle newspaper, Jeff Lyon who worked alongside Bill from 1974 until 1981 stated ‘I could tell he was somebody different right away. If it took him 80 hours to complete work for which he’d only get paid forty, he’d do it. Unfortunately he was a bit slow sometimes. I remember once a fellow brought him a frame for some braze-on work and painting. It took him so long that when he finally finished it and called up the fellow, someone at the other end of the line said, “Oh I’m sorry, Harry’s been dead for six months now”. Nonetheless he was still fussy about detail.’

More recently, Paul Mepham of Harry Perry Cycles told me of a time when he was desperate to get a frame back from Bill and was told it would be ready that evening at 7pm. Paul arrived but did not leave the workshop until 11pm only to be stopped by the police suspecting something suspicious until the situation was explained and the mention of Bill by name! Whilst these are amusing anecdotes it does demonstrate the long hours that Bill put in at his workshop, ‘12 -14 hour days’ according to Ron Ash. Sands tells us that Bill made few so called ‘standard’ frames sold as Avecaise, a name made up one assumes of left over letters from a kind of ‘Letreset’ used for the down tube decals.

Jeff Lyons still uses this name for his less prestigious frames. Sands also waxes lyrical about the number frames made for foreign buyers but this is not exactly borne out in the frame book where it is clear a great many local club folk were his customers but to be fair many entries show little more than the name of the customer. In his eulogy Ron Ash also emphasises the links with the US –‘one customer flew into Heathrow, collected his new machine and flew back the same day…’ It is also interesting to note the number of customers requesting welded lugless frames which from my memory were not very common in the 1970s/80s unlike today.

In March 1981 Bill and Jeff were delegates on a visit to Reynolds organised by Cliff Shrubb largely to check out the criteria for building frames in 753 tubing. They were accompanied by what might be described as the cream of Southern frame builders, notably Ron Cooper, Alec Bird, Stan Pike, Tom Quick, Chas Roberts, John Spooner, Mick Coward, Ken Rogers and Barry Witcomb et al. Like others Bill carried out the tests for accreditation but only five frames were built in as many years.

Philbrook Innovations and attention by the Press.

Bill was always able to make almost anything from scratch. If one asked for a brazed-on bottle cage in the 1960s these would be more than likely made from solid steel rod, filed, brazed on and drilled. But more importantly many unique touches could be found on a Philbrook frame. Bill could produce wonderful lugless frames that could be made more streamlined as in the time trial frame built for Ian Silvester in 1982 but Griff King-Spooner recalled similar innovations for Tom Smith’s frame a decade earlier with an extraordinary paint job that was ahead of its time.

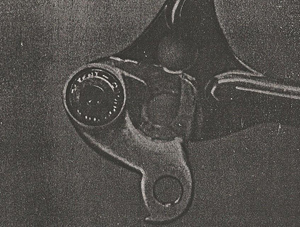

This frame and one made by him for Jeff Lyon can be seen on the Classic Rendezvous website that exemplifies his stunning workmanship and all share the same attention to detail. The writer has recently acquired a road frame which shares the same webbed chainstay bridge and ‘Philbrook’ designed dropouts with brass facets in common with the afore mentioned frames.The lugs are greatly reduced and extensively filed. It was his first frame built with Reynolds 753 tubing. Beside the numerous little Philbrook touches and finish of his frames there were more important innovations. Some of his beautiful rear drop-outs featured a gear hanger that could be swung back to allow easy extraction of the back wheel (see image below):

Perhaps most intriguing was a tandem with a step down countershaft system developed with the help of Jeff Lyon. These caught the attention of the French press and articles by Claud Lavaud appeared in two editions of ‘Le Cycle’ under ‘Technique’ in September 1982 and October 1984. Bill would be willing to help out in an emergency as occurred in October 1977 when a sponsored charity float consisting of a large firemans helmet fixed on top of a homemade tricycle collapsed on Chatham Hill on its way to Mainz from Watford. Bill came to the rescue to repair the broken axle and the incident appeared in the local ‘Chatham Standard’ under the caption ‘NOW CAP THAT – Cycle expert Phil rescues helmet-trouble firemen’.

Bill could also turn his hand at making ‘penny farthings’ for children. There is a famous photo of him outside his shop with one he made commercially ‘for a local business man’. One was also made for his Granddaughter around 1982 according to a note by Mary to Norman. Sands wrote ‘ Bill’s health began to fail, so when the Chatham Dockyard was closed, one of the craftsman there, Rod Kennison, who raced tandems, was taken on to run the retail side of the business. The times were changing, one of the last orders was for a BMX. When the very last frame was made in February 1986, of almost 1000 frames made by Bill in his lifetime, only 333 carry the Philbrook name, each one an individual gem, possibly surpassing his earlier output’

Perhaps the last article to feature Bill was one written by Tom Bogdanowicz in the May 1987 edition of ‘Bicycle Action’ that featured a number of current frame builders showing Bill alongside Les Rigden, Tom Board and Chas Roberts. However, Bill had been ill for some time suffering from cancer. It was all too late as Bill had already passed way on the 22nd March. Tributes were paid by Ron Ash of the Wigmore CC at a Kent Vets Meeting and the Fellowship of Kent and Sussex Cyclist who honoured him with a posthumous award of the Fellowship Trophy in April that year. His shop remained open for a number of years and by the early 90s was run by Rod Kennison’s son Richard. At the time of writing some 20 years later the whole area has been redeveloped and nothing now remains of that shabby run down shop in downtown Gillingham where at one time magic was performed.

Postscript

I am grateful to Norman Cole for passing on his dossier to me and only sorry it has taken me so long to write something. The outcome is done to the best of my ability. However, I hope the framework is there for further contributions and corrections which are of course welcome.

Those wanting information from the copy of Bill’s frame building book are welcome to contact me by E Mail at clarkesharman@aol.com

I am grateful to Griff King Spooner for providing me with the part made drop-outs from Bill’s workshop

Bryan Clarke

December 2013

Details of Philbrook work:

Philbrook standard lugs where he has enlarged the windows, also unique Philbrook manufactured rear end

Posted: Saturday 06th June 2020

Contents

- Introduction and Bill's Career

- Bill Philbrook at work

- Superlight frame

- Drawing for Norman’s Tandem

- Bill as a club cyclist

- 3 Part from Bill's Workshop

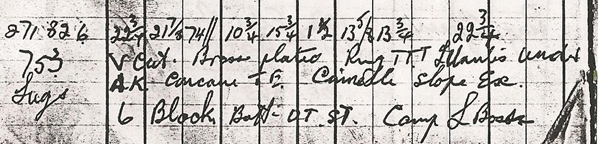

- Norman’s notes

- Bill with Jeff’s scooter

- Bill produced frames for Meridian Cycles

- Head lugs and seat cluster images

- Bill’s Frame Building Record Book

- Bill’s frame workshop book

- Harry's memory

- Jeff Lyon outside Bill’s workshop

- Philbrook Innovations and attention by the Press.

- beautiful rear drop-outs

- Le Cycle edition

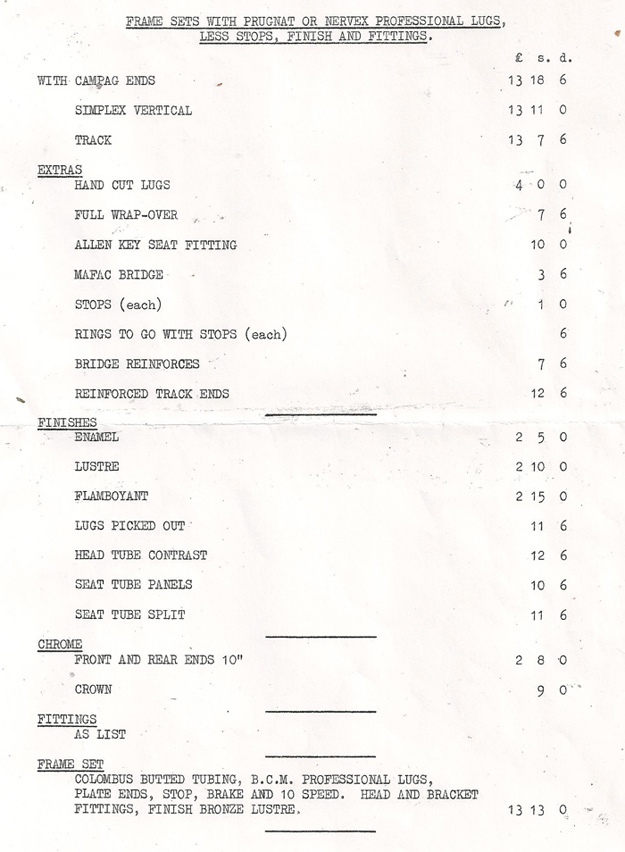

- price list

- Details of Philbrook work

- Philbrook work

- Images of Bill Philbrook made using hand cut Grandini lugs

- Bill Philbrook made using hand cut Grandini lugs

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.